When you are going to select products for your indoor climate, there are many things you need to take into consideration. There are many different types of products and variants, but how should you find the right one?

First of all, you need to determine the indoor climate that the building requires, as well as what demands have to be satisfied. In addition to ventilation and heating, you also need to know whether cooling is required and what the controlling parameters will be. Where can the products be placed and is there space? What are the wishes in terms of integration with the rest of the internal architecture and what are the applicable acoustic requirements?

Getting an idea of the dimensioning in order to make the right choices

The sizing of room products can take place in several different ways, but first of all it is necessary to define the actual dimensioning value. For example, if we look at a classroom measuring 6 x 10 metres that is to be occupied by 30 people, and assume hygiene airflows that can be 0.35 l/s and m2 + 7 l/s, this would produce a dimensioning value of approx. 230 l/s. However, an air quality of max. 1000 ppm carbon dioxide content is often also required, and what is the CO2 content at 230 l/s? The calculation is already starting to become tricky.

When more demands and parameters that affect sizing arise, a product selection program comes in handy. Product selection programs for room units often have a CO2 calculation, for example. The carbon dioxide content in the first calculation for the classroom shows that the value is too high, at 1049 ppm. Using the calculation program, I can determine that an additional 20 l/s are required, i.e. 250 l/s, in order to maintain 1000 ppm.

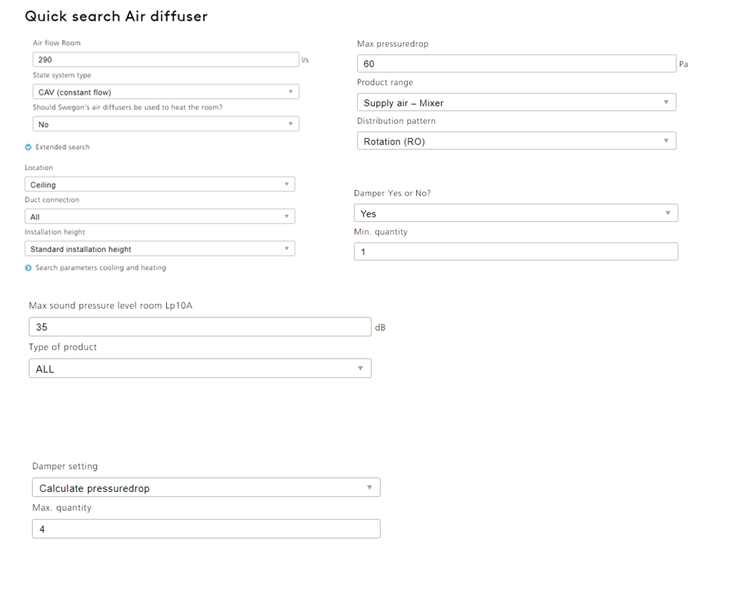

Another demand that can occur in combination with CO2 is a max. room temperature or a demand for a cooling capacity per m2, e.g. 35 W/m2. Using the calculation program, I can determine that 290 l/s are required. So now we have gone from 230 l/s to 290 l/s as the design flow!

Find out more about indoor environment factors and how they affect us here.

Finding products that suit the system

The next step is to look at the conditions. Which systems are available? Is waterborne cooling available or does the entire demand have to be managed using air, and where can the product be placed? Here, too, the calculation programs can help to filter out suitable products. By filling in your needs, you obtain a more precise hit list.

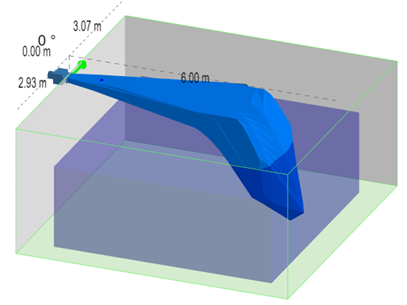

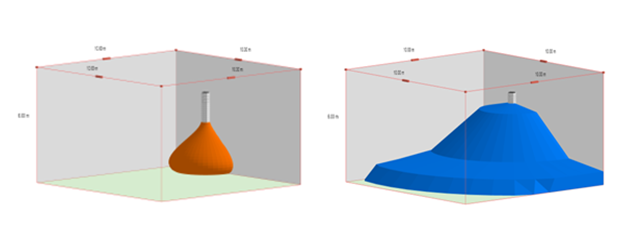

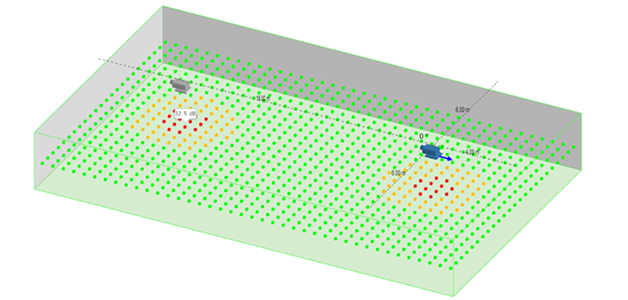

If you are going to perform cooling with air, it is often difficult to achieve a solution with rear edge/wall products. It is even more complicated if you want to use varied airflow, because it is very difficult to perform the calculation yourself and ensure that the air does not “drop” from the ceiling, creating draughts. This can clearly be seen in the calculation program where the isovel is shown.

One way of ascertaining how the air moves in the room is to use the product brochures’ throw length diagrams, for example, which can give an idea of the actual situation. However, this is a simplified picture that may not be sufficient. For this reason, the throw lengths in the room are often calculated at isothermal air supply (the same room and supply air temperature). When you use air that is below room temperature, the results are fairly uncertain. Here, too, the calculation programs can help. Because the calculation programs calculate isovels, you can get a clearer picture of how the air is moving. You can also see a number of products as well as collisions with other air jets or walls. In this way, you can increase the quality of your product selection and avoid unpleasant surprises afterwards.

Selecting the number of products

If you have larger airflows, it is almost always better to distribute the air between several products rather than trying to squeeze the entire flow into one and the same product. In addition to reducing the risk of draughts, you can reach a larger proportion of the rooms and reduce unventilated location. It is also common to have combinations of different products in the same room. In a conference room, for example, you often use both air diffusers and chilled beams to satisfy several different needs. With a good calculation program, you can get a better picture of a room and see more clearly whether or not there will be any draughts with a particular product. In this way, you also get help to select the correct combination of products that are correctly sized for the room in question.

How will the climate in the room be controlled?

When choosing a product, you also have to consider how the system will be controlled. Are you going to ventilate with constant flows (CAV) or do you want to adapt the ventilation according to the current requirement (VAV/DCV)? Here, too, there are different products that are suitable to varying extents, depending on how the room is to be controlled.

If you want to perform heating and cooling with the same product, you need to look into both the heating and cooling mode, as in the example below.

If you are using a DCV system, you need to be able to calculate how the flow varies over time. The flow is not always the same, and you can use different set points depending on whether the room is occupied or not and, if so, to what extent. However, it is not always the load caused by occupants that is the controlling factor of the airflow. In a room that is facing south or west and that has large windows, it is often the solar radiation instead that determines the cooling requirement.

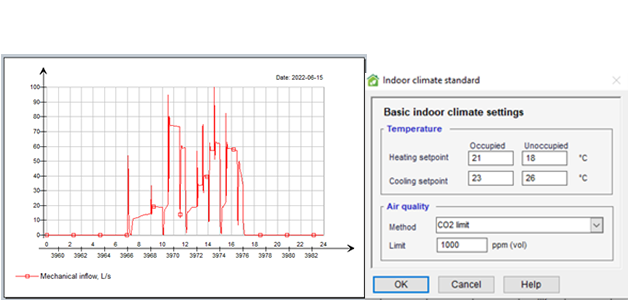

If you are using a DCV system, you need to be able to calculate how the flow varies over time. The flow is not always the same, and you can use different set points depending on whether the room is occupied or not and, if so, to what extent. However, it is not always the load caused by occupants that is the controlling factor of the airflow. In a room that is facing south or west and that has large windows, it is often the solar radiation instead that determines the cooling requirement. (Left) Airflow chart showing DCV. (Right) Settings program for controlling the airflow.

(Left) Airflow chart showing DCV. (Right) Settings program for controlling the airflow.

Acoustic requirements also part of the calculation

Sound is almost always part of the requirement specification, where the sound level may not exceed a maximum limit. In order to calculate sound, many things need to be taken into consideration. What type of room is it, how big is it and what attenuation is present there? How many products are there in the room, where are they placed and what sound comes via the duct system? The suppliers’ product sheets often present sound levels, but these are almost always based on a sample room with a certain level of acoustic attenuation, and this often does not correspond with the room in question for which you are going to perform calculations. In this situation, a calculation program can be extremely beneficial. Performing complicated acoustic calculations is no longer as difficult.

The use of calculation tools

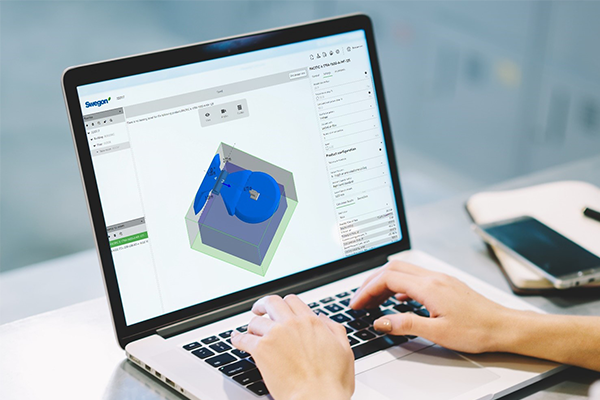

Using the calculation program is positive, although there is still more to be desired. Nowadays, it is rare for one and the same program to be able to perform all the calculations, to achieve this, different programs often need to be used in combination. By getting the programs to work together, however, you can improve the efficiency and quality of your solutions. For example, a smart option can be to get a product selection program to work together with a CAD program.

Another problem that often faces software developers is to find solutions that satisfy the user’s needs. Weighing functionality and opportunities against having a calculation program that is easy to understand and start to use is a challenge. Whatever you do, someone will be dissatisfied – one person will say that functions are missing, while another will find the tool too complicated. In this case, a good solution can be to have a single program but with different levels in order to satisfy different types of users, and here too, it is important for the programs to be interconnected so that you avoid the additional work of filling in data multiple times.

The most important aspect of a product selection program is that it should be a tool that helps the user to perform calculations easily, but above all as accurately as possible. The data that is presented must be correct, regardless of whether it is good or bad. This so the product selections for a project can ultimately be as good as possible, both matching the customer’s needs and providing a comfortable indoor climate.

Read more and try out the Swegon product selection tools here

.jpg?width=75&name=sigvardsson_220628_0008_small_webb%20(1).jpg)

.jpg?width=75&name=magnus%20andersson_550x550%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)