Climate systems fulfil the same purpose of adapting ventilation and air conditioning to varying levels of activity in our premises. In general, it is possible to achieve higher energy savings, more cost efficiency and a better indoor climate with a more advanced system.

The need to cut carbon emissions without compromising on comfort conditions and occupant health & well-being has presented our sector with considerable technical challenges.

Smaller ventilation ducts

Water is a very efficient energy carrier, using it as a medium for carrying energy for cooling/heating means the size of ventilation ducts are significantly smaller, the ventilation rate is maintained at a lower rate to meet the air quality and humidity requirements. Furthermore as the ventilation doesn’t need to be at a lower temperature the ventilation ducts don’t require as much insulation, which means that you can save even more space and money on the duct system.

Saving a couple of decimetres in building height on each floor can allow the designer to fit an extra floor within the framework of the building permit, increase the ceiling height in the offices, or just save on construction costs. More space on each floor provides greater rental income, which can very quickly weigh up against a potentially higher initial cost for a water-based climate system.

Individual comfort control

In recent times it is typical to be able to set exactly what temperature you want in a car. Even if you do not get the exact set temperature, the feeling of having control over the temperature is important. In most cars, the temperature on the driver's side and the passenger side can also be regulated independently. This is because what is perceived as the best possible comfort is individual.

By installing a climate system based on comfort modules or active cooling beams, it is possible to regulate the temperature individually, within a larger temperature range than with a system entirely based on airborne cooling. A relatively large amount of air is set in motion when the supply air induces a secondary flow through a chilled beam, but by utilising ceilings and walls to distribute the air in the room, high velocity air in the occupied zone can be reduced. This provides the conditions for creating a draft-free climate. Since no fan is used to circulate the room air through the heat exchanger in the chilled beams, the sound level can also be kept to a minimum.

Studies show that people who work in an environment with poor thermal comfort have poorer performance ("Ten questions concerning thermal and indoor air quality effects on the performance of office work and schoolwork" by David P Wyon). A waterborne climate system with chilled beams or comfort modules helps to meet future energy requirements and provides low operating costs without having to neglect thermal comfort.

Lower operation costs

Active chilled beams utilise a supply air connection and high pressure nozzles to induce the room air through the heat exchanger, producing an induction ratio of around 1:4. This of course negates the need for a fan meaning a significant reduction in fan energy used in the whole building.

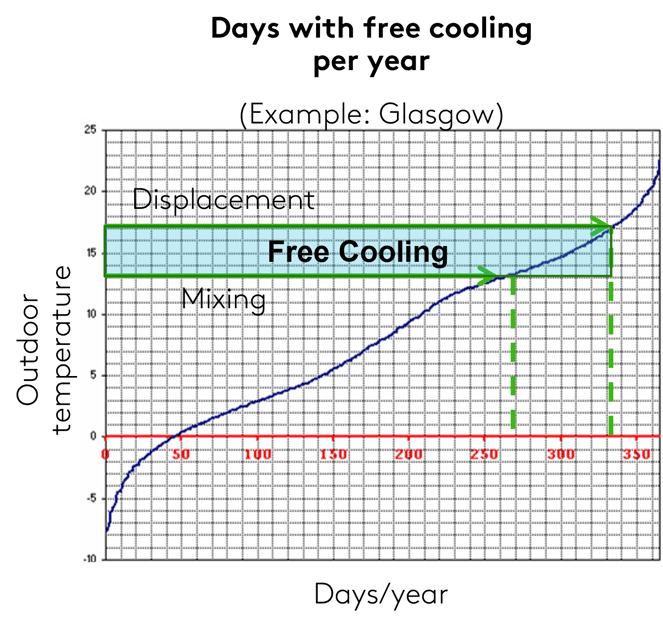

Chilled beams run on a elevated chilled water temperature of around 14°C - 17°C, which means a much higher period of free cooling & lower energy consumption when compared to other water cooling methods.

Chilled beams run on a elevated chilled water temperature of around 14°C - 17°C, which means a much higher period of free cooling & lower energy consumption when compared to other water cooling methods.

Another way to save energy is to provide heating through the 1-way air distribution comfort module, the forced convection of the room air through the heat exchanger creates the conditions for an efficient heat transfer from water to air. This means that the temperature on the heating coil can be lower and thus the pipeline losses can be reduced. Heat pumps can also be utilised to generate higher efficiencies and a reduce the carbon footprint.

Lower maintenance costs

A system with active chilled beams is almost maintenance-free. Since air is moving at a low velocity over a dry coil it significantly reduces the amount of dust and contaminants in the supplied air, consequently there are no filters or drainage requirements. In dusty environments you may need to vacuum the exchanger and visible parts at the appropriate intervals. Otherwise, the system manages itself, needs minimum servicing and has a long service life.

Making improvements with system upgrades

Given that each project has unique parameters and caters for different requirements, it follows that there can be no universal, ‘one-size-fits-all’ climate system.

The amount of fresh air supplied to the space is based on minimum ventilation requirements at maximum occupancy. During commissioning the nozzles in the chilled beam are set to a specific pressure (k-factor) based on this ventilation rate which ensures a good balance between good induction and minimal noise.

For this reason varying the supply air volume at any stage after commissioning will have a significant impact on the performance of the unit. If the supply air volume is too low it will affect the efficiency of the induction process, if its increased by too much the higher pressure in the nozzles may cause additional noise issues.

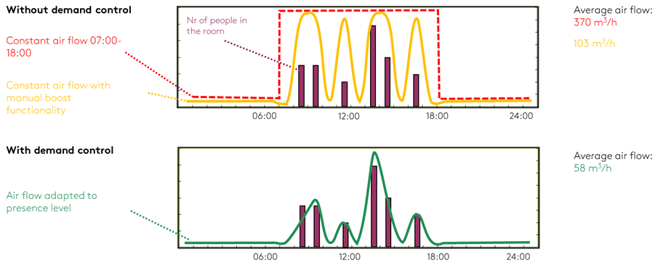

Outdated ventilation and indoor climate systems in existing properties hold great potential for upgrade and improvement. Solutions for variable airflow, VAV, can reduce the energy used by fans, heating and comfort cooling significantly compared to solutions for constant airflow, CAV, which are typically installed in existing buildings. Meanwhile, there is high potential for improving the indoor climate, which benefits the well-being and performance of the occupants in a building.

End users wishing to benefit from a variable air volume system where air flow can be ramped up at peak occupancy and reduced during off peak times may be restricted somewhat with the above issues. A basic VAV system may be perfectly adequate for small-scale projects, where the demand scenario is less advanced but where the investment cost is a critical factor. For projects where the indoor climate requirements are more stringent and the building is likely to need to be environmentally certified, you’ll be looking for a more advanced DCV system.

A demand-controlled room air conditioning system is energy efficient because the system regulates exactly as required. It does not ventilate, cool or heat too much - which costs energy - nor too little - which affects comfort, but only as much as is needed.

Using VAV technology alongside an occupancy or Co2 sensor gives the end user demand control for optimum efficiency. In today’s world where energy conservation is becoming increasingly important, this provides a cost-effective solution to bring the benefits of a variable air volume system to any project.

.jpg?width=75&name=Image%20(5).jpg)

.jpg?width=75&name=magnus%20andersson_550x550%20(1).jpg)

.jpg?width=75&name=0%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)