Air handling units equipped with rotary heat exchangers with a sorption coating bring significant opportunity for energy and carbon emission reductions, while also improving the indoor environment. But what exactly is it that make them so advantageous? Here is a step-by-step guide to understanding what makes sorption rotor technology work so well, with a special focus on cooling applications.

Sorption technology

The material of the sorption coating has the ability to absorb moisture from the air when the humidity is high and to release it when the humidity is low. This means moisture is recovered; which means we get latent energy recovery as well as sensible energy recovery.

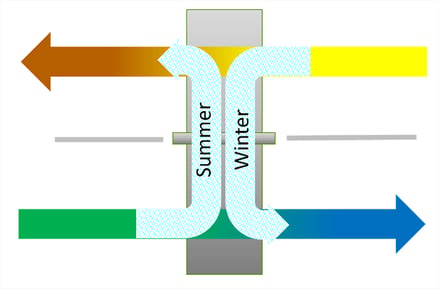

In the summer when the outdoor air is humid, moisture is removed from the outdoor air and released to the exhaust air. In the winter the outdoor air has a low moisture content so the sorption coating can recover moisture in the extract air and release it to the supply air. This brings two benefits in cold outdoor conditions. Firstly, the raised humidity in the supply air is beneficial for the indoor environmental quality and secondly, because the moisture is removed from the rotor there will be much less risk of frost and the need for defrosting is more or less avoided. This means that the sorption rotor saves some heating power during the winter.

In summer, when the humidity is higher, moisture is removed from the outdoor air and transferred to the exhaust air. In winter, moisture is transferred from extract to supply.

Humidity transfer happens when there is a difference in specific humidity between the extract air and the outdoor air. The amount transferred is given by the latent efficiency performance of the rotor.

Latent efficiency of supply air = (x22-x21)/(x11-x21 ) %

Where

x11 = specific humidity in the extract air g/kg

x21 = specific humidity in the outdoor air g/kg

x22 = specific humidity in the supply air g/kg

Cooling Power reduction

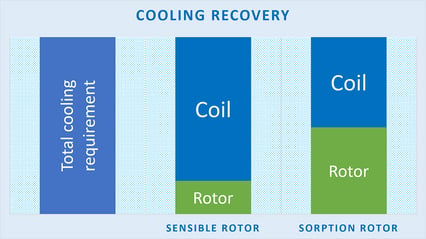

Because of the latent energy recovery in the rotor, we significantly reduce the cooling power demand in the cooling system. Even with a plain aluminum heat exchanger, we get sensible cooling recovery

This diagram illustrates just how much more cooling recovery we get with the sorption rotor. The example is based on 30°C outdoor air and a supply temperature of 12°C. The sensible rotor provides about 20% of the cooling while the sorption rotor is able to provide about half of the cooling power. This will vary depending on the conditions but shows that the cooling power reduction is very significant with the sorption rotor.

Cooling Energy reduction

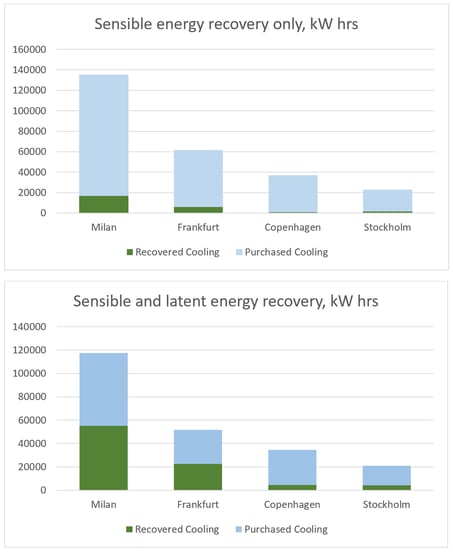

The cooling energy reduction will, of course depend on the duration of warm weather. The following example has been calculated with the following conditions:

Airflow rate: 2 m3/s

Supply air temperature: 16°C

Extract air temperature: 22°C

- The sorption rotor has a temperature efficiency of 82% and a humidity efficiency of 74% in the summer.

- The aluminum rotor has a temperature efficiency of 82% in the summer.

- The pressure drop of the sorption rotor is about 10 Pa more than that of the aluminum rotor so the difference in fan energy is small.

- The first diagram shows the cooling recovery using the aluminum rotor and the second diagram shows the recovered cooling using the sorption rotor.

Compared with cooling equipment, sorption rotors are relatively simple machines so we have the additional benefit that the maintenance cost is much lower per kW-hour.

Power peak reduction

Occasionally the weather brings higher temperatures and humidity levels than that of the design. This will, of course, lead to an increase in the temperature indoors. The recovered cooling power of the heat exchanger is proportional to the temperature and humidity difference, so when the outdoor condition rises and the difference between extract and outdoor condition increases, we get more recovered power.

Humidity recovery

In cold weather, outdoor air that is heated will have a low humidity so the indoor air will become dry. In these conditions, the sorption rotor recovers moisture in the extract air and returns it to the supply air; which means the indoor air is kept more moist and more comfortable and hygienic. It may be necessary to add moisture using humidification and then the sorption rotor brings the benefit of a lower humidification load so the installation will be cheaper and the running costs lower.

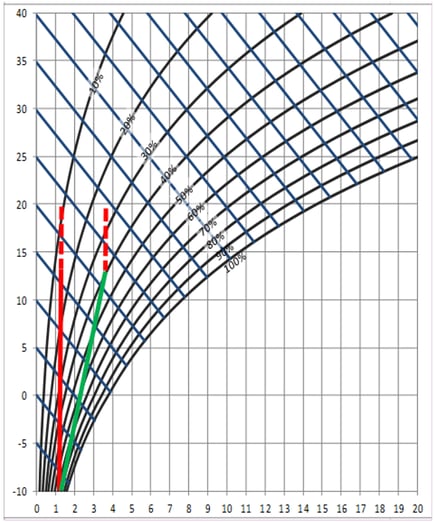

In this example cold air is heated by the rotor to 13°C and is then reheated to 20°C.

Red line= aluminum rotor, Green line = sorption rotor

Reduction of humidification powerWe can see from the diagram that the cost of humidification is significantly reduced. If we assume the supply air condition needs to be 30% to 40% relative humidity, then instead of needing to add about 5-6 g moisture per kg of air we will only need to add 2-3 g moisture so the cost will be halved by using the sorption rotor.

If using an adiabatic humidifier, then the sorption rotor can offer the benefit of reduced reheat power and reduced water consumption.

Leakage

The disadvantage with rotary heat exchangers is the problem of internal leakage between extract and supply air. If properly designed and installed, the leakage can be reduced to less than 1%. The rotor needs to be fitted with effective seals, a purging sector and the system needs to be set up with the correct pressure balance.

To get the correct pressure balance, the fans need to be correctly positioned. Both the supply and the extract fans are best placed upstream of the rotor in their respective air streams. It will often be necessary to introduce a pressure reducing device in the extract air.

Conclusion

The ability of the sorption rotor to recover both sensible and latent cooling has profound impact on both the cooling power demand and the cooling energy consumption. The cooling system is made much smaller saving space and cost. A smaller chiller also means a reduced amount of refrigerant. All taken into account, a sorption type rotor have a number of significant advantages in terms of energy savings and reduced investment costs, while securing a higher level of comfort and well-being.

For the latest development in the field of sorption technology, keep an eye out for the new generation RECOsorptic rotary heat exchangers for our Swegon GOLD air handling units. Launched in late 2021, these will set a new standard for sorption rotor performance. Combined with the smart control functionalities of the GOLD, minimising internal leakage, it brings out the full potential of the sorption rotor technology.

.jpg?width=75&name=Image%20(5).jpg)

.jpg?width=75&name=magnus%20andersson_550x550%20(1).jpg)

.jpg?width=75&name=0%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)