Swegon has signed a Letter of Intent with steel producer ArcelorMittal to buy steel with significantly lower climate footprint than before, being produced from mainly recycled material and with 100% renewable energy.

”To drive initiatives towards a green transition is one of our most important sustainability goals, and by this agreement, Swegon takes an important step to reduce our CO2 footprint” says Andreas Örje Wellstam, CEO for Swegon Group.

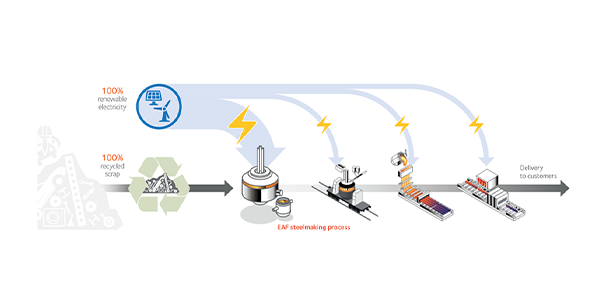

”To reduce our dependency on fossil fuel, like coal in the production of our products, is one of the most important challenges we have. Today, approx. 70% of all steel produced is produced from a blast furnace process, where coal is the primary source of energy and subsequently CO2 emissions are high. By using EAF technique, Electric Arc Furnace, recycled steel can be used as raw material and electricity is the primary energy source, which means that the process in principle can be entirely carbon dioxide neutral, if the electricity is generated from a fossil free source of energy”, Andreas continues.

ArcelorMittal is one of the largest steel producers in the world and we have a target to reduce our Scope 1 and 2 CO2 emissions by 35% by 2030 in Europe. The transition from Blast Furnaces towards Direct Reduced Iron (DRI) with Electric Arc Furnaces (EAF) in the production process is an essential part of this, and we are proud to have announced a large number of DRI-EAF investments. For the moment ArcelorMittal offers our customers the possibility to buy XCarb® RRP steel (recycled and renewably produced) , produced using a high proportion of recycled material and renewable energy” says Laurent Plasman from ArcelorMittal.

The first delivery of XCarb® steel to Swegon will take place early 2023.

.jpg?width=75&name=Image%20(5).jpg)

.jpg?width=75&name=magnus%20andersson_550x550%20(1).jpg)

.jpg?width=75&name=0%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)