The duct system pressure drop has a significant impact on the SFP. But what are the factors we need to focus on when reducing SFP? Lets take a closer look at that.

Specific fan power, SFP, is the total electrical power of the fans in an air handling unit in kW divided by the supply air flow or the exhaust air flow depending on which of them is the largest.

Knowing the price of electricity, the SFP tells us what the cost of ventilation is. The cost in terms of CO2 emissions can also be calculated.

Several definitions of SFP exist. The term SFPv has been in existence for many years now and is commonly used by Nordic manufacturers while SFPint is found in the ErP Regulation 1253, for example.

SFP has been around for many years and there is a general trend towards lower SFP values driven by the need to reduce energy consumption and CO2 emissions. 30 years ago SFP values were often over 3 kW/m3/s but today we typically see values of 1,5 kW/m3/s and even lower are not uncommon.

This means we have halved the energy cost of operating ventilation systems!

What are the factors we need to focus on when reducing SFP?

It is generally the Air Handling Unit or fan manufacturer providing the SFP values and it is easy to think that the SFP is their responsibility but what is SFP really?

Specific fan power, SFP, is the total electrical power of the fans in an air handling unit in kW divided by the supply air flow or the exhaust air flow depending on which of them is the largest.

Knowing the price of electricity, the SFP tells us what the cost of ventilation is. The cost in terms of CO2 emissions can also be calculated.

Several definitions of SFP exist. The term SFPv has been in existence for many years now and is commonly used by Nordic manufacturers while SFPint is found in the ErP Regulation 1253, for example.

SFP has been around for many years and there is a general trend towards lower SFP values driven by the need to reduce energy consumption and CO2 emissions. 30 years ago SFP values were often over 3 kW/m3/s but today we typically see values of 1,5 kW/m3/s and even lower are not uncommon.

This means we have halved the energy cost of operating ventilation systems!

What are the factors we need to focus on when reducing SFP?

It is generally the Air Handling Unit or fan manufacturer providing the SFP values and it is easy to think that the SFP is their responsibility but what is SFP really?

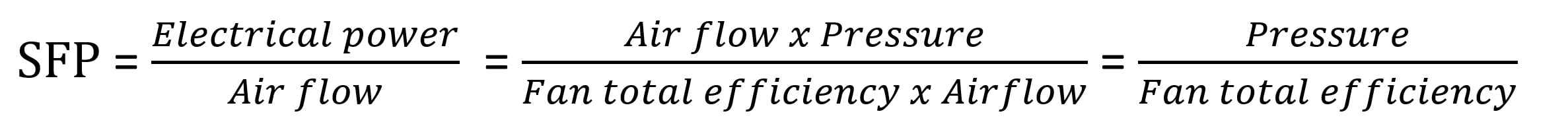

So this means that SFP is all about Pressure and Efficiency.

To reduce the SFP we need to reduce pressure drop and increase the total fan efficiency.

Fan and motors today are well developed and the efficiency offered is high considering the need for flexibility in airflow and pressure. Further developments can be expected but every one-percent of efficiency improvement is very demanding and costly.

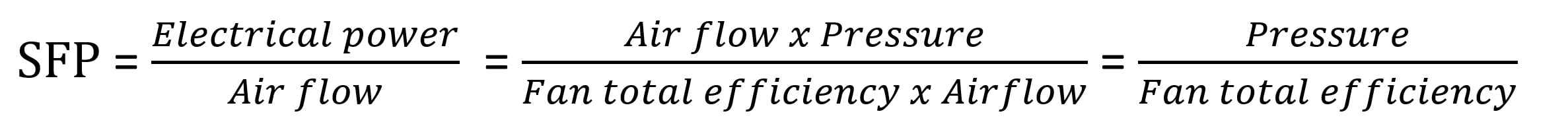

In the chart below we will take a closer look at the role pressure plays in the SFP calculation. Statistically we see that the average total pressure fans are selected at is about 600 Pa but it varies a lot- the large majority of units selected lie between 500 Pa and 700 Pa but we see many cases much higher than 700 Pa. Obviously, the higer the pressure, the higher the SFP. We can also see a clear trend that pressure increases with airflow.

To reduce the SFP we need to reduce pressure drop and increase the total fan efficiency.

Fan and motors today are well developed and the efficiency offered is high considering the need for flexibility in airflow and pressure. Further developments can be expected but every one-percent of efficiency improvement is very demanding and costly.

In the chart below we will take a closer look at the role pressure plays in the SFP calculation. Statistically we see that the average total pressure fans are selected at is about 600 Pa but it varies a lot- the large majority of units selected lie between 500 Pa and 700 Pa but we see many cases much higher than 700 Pa. Obviously, the higer the pressure, the higher the SFP. We can also see a clear trend that pressure increases with airflow.

The role pressure plays in the SFP calculation.

In this total pressure there is one part that is the internal pressure drop of the air handling unit while the rest is the external pressure. The average external static pressure we see is 300Pa on the supply side and 280 Pa on the extract side. This means the external static pressure is roughly half of the total pressure, which means it is responsible for half of the SFP value on average.

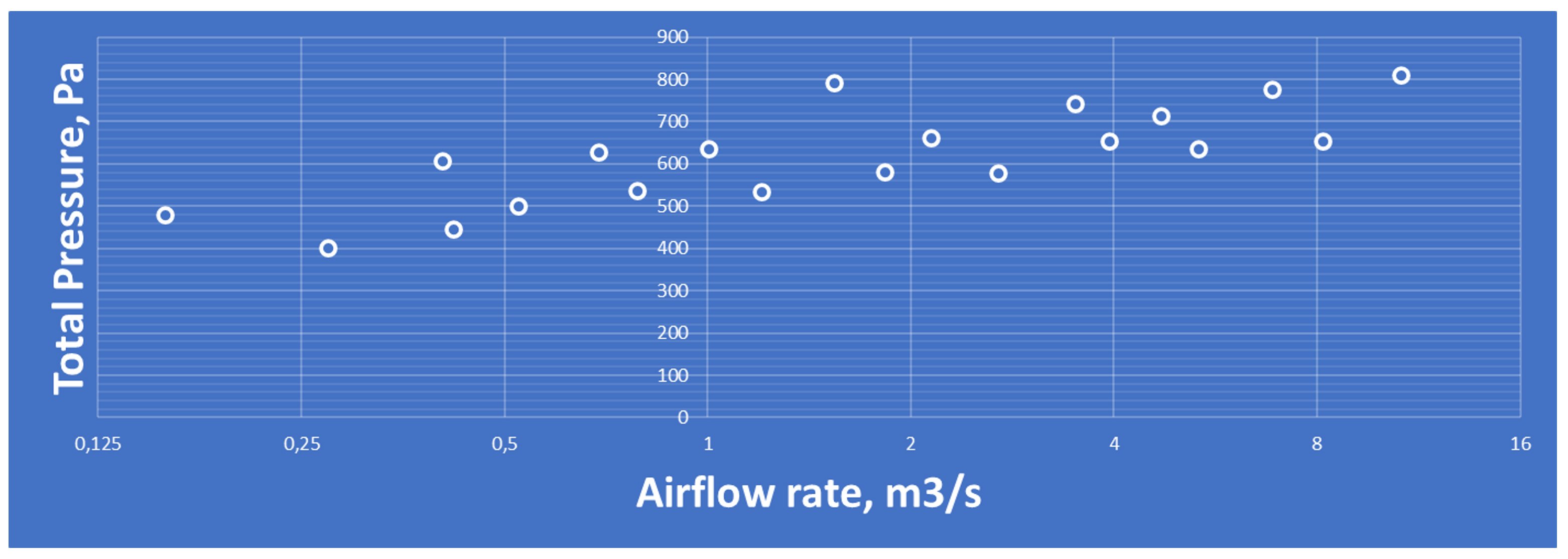

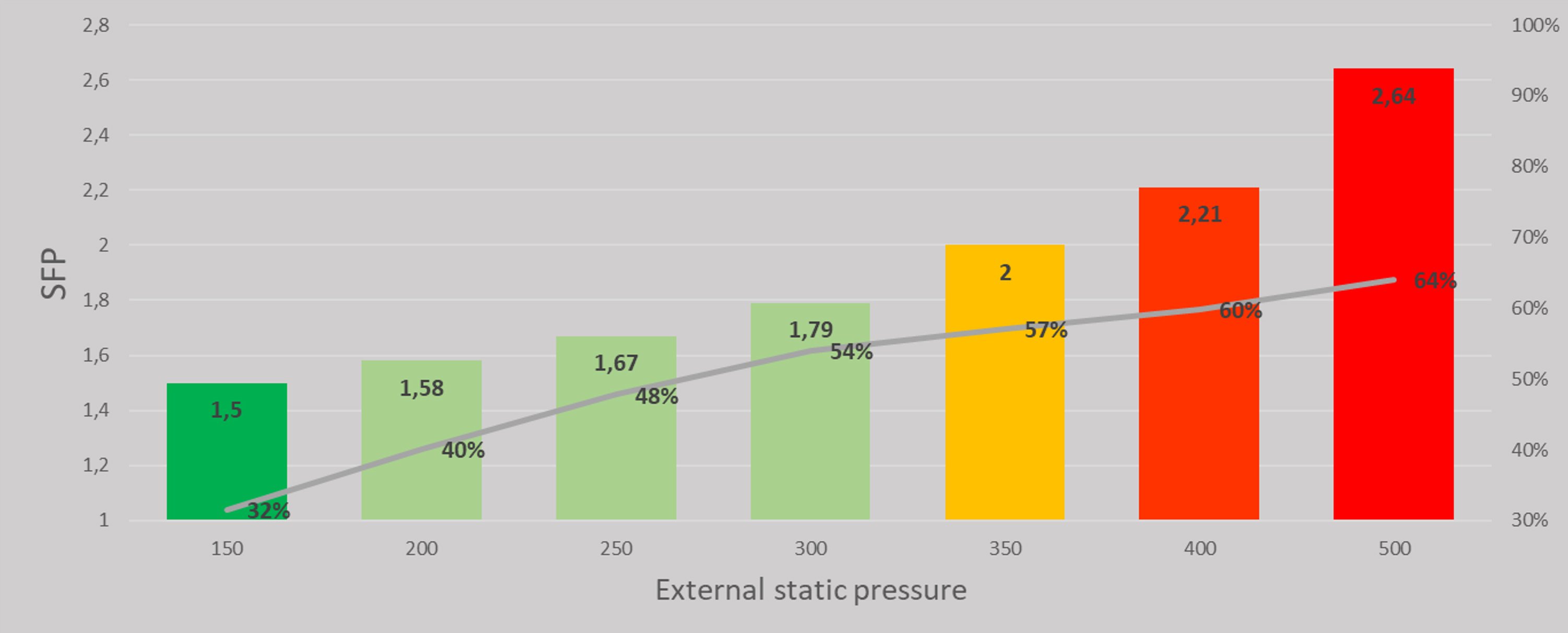

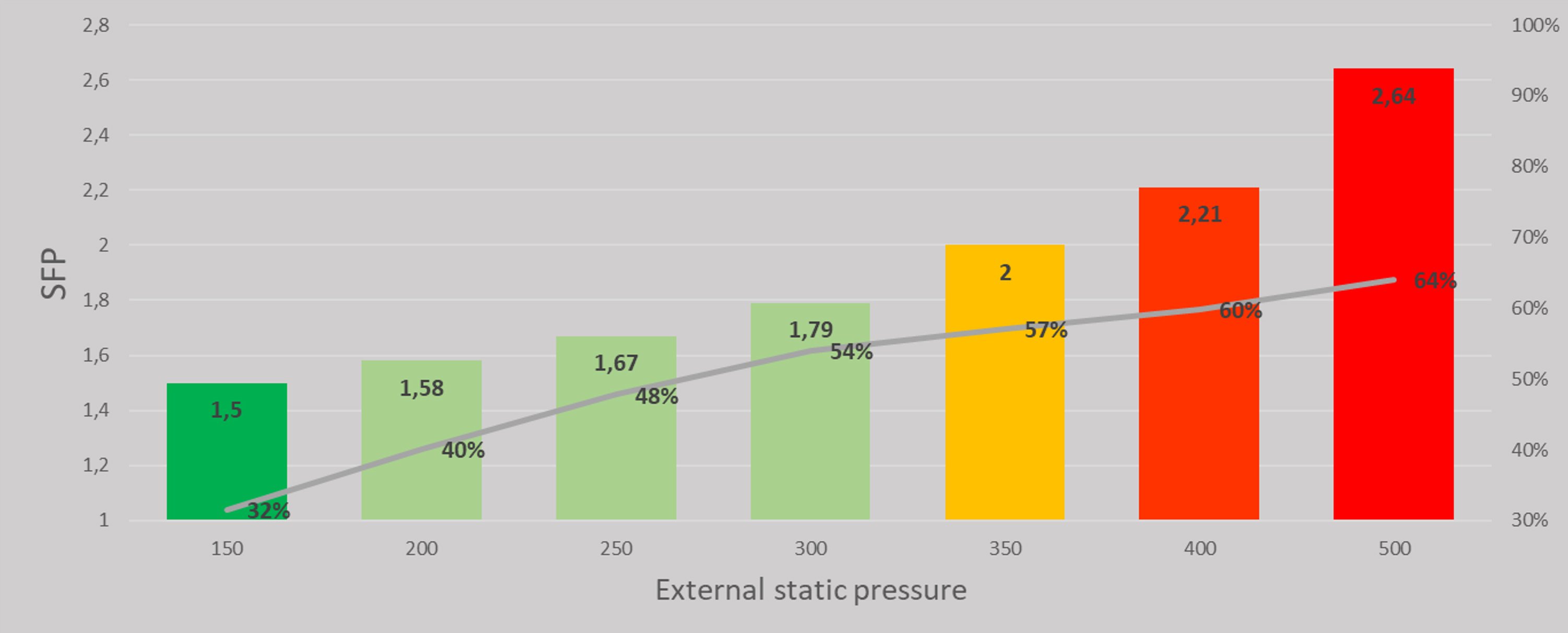

We can see from the formula above that SFP increases with increasing pressure. In this example, in the chart below, an air handling unit with rotary heat exchanger with supply and extract fans is calculated with the same airflow and components but with different external static pressures:

We can see from the formula above that SFP increases with increasing pressure. In this example, in the chart below, an air handling unit with rotary heat exchanger with supply and extract fans is calculated with the same airflow and components but with different external static pressures:

Air handling unit with rotary heat exchanger chart.

The unit has heating and cooling included and with an external pressure of 150 Pa the SFPv is 1.5 kW/m3/s. The external pressure represents 32% of the SFPv. At 350 Pa the SFPv is 2.0 kW/m3/s with the external pressure accounting for 57% of that. When the external pressure is so high, it is not easy to compensate for it in the selection of the air handling unit.

Duct system pressure has a profound affect on the SFP of the building and low pressures are essential for low energy buildings!

It is important to note that the efficiency of the heat recovery device is related to pressure drop so any reduction is pressure drop there will probably mean a lower heat energy recovery.

The pressure drop of the air handling unit is proportional to velocity. If the SFP is pressed to very low levels, that inevitably means lower velocity and that can lead to control stability problems.

To get a low SFP and good function it is important to get a good balance between duct system pressure and air handling unit internal pressure.

Statistics show that duct system pressure increases with airflow rate. This is quite logical because large airflows often serve large systems with long and complicated duct runs. This means that it is worth considering splitting up the system into some smaller systems each with its own air handling unit to reduce SFP.

.jpg?width=75&name=Image%20(5).jpg)

.jpg?width=75&name=magnus%20andersson_550x550%20(1).jpg)

.jpg?width=75&name=0%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)