To create a healthy and comfortable indoor environment where people can perform an thrive, it is important to ensure good air quality. This, without creating noise and without causing discomfort due to high air velocities, temperature gradients or radiant asymmetry. The challenge is to design a solution for heating, ventilation and cooling (HVAC) that meets the requirements for the quality of the indoor environment, energy consumption, investment and life cycle cost. The options are many, this blog focuses on one choice of air terminal device which can provide good air quality and thermal comfort in a very energy efficient way - active chilled beams.

To ensure good air quality, pollutants need to be removed which is done by ventilation. In order to design an energy efficient system, it is advantageous to use mechanical ventilation where energy can be recovered from the extract air. Ventilation can provide comfort cooling by supplying primary air of lower temperature than the room air. In situations where the outside air is colder than the room temperature, this becomes very energy efficient as the cold outside air provides free cooling. However, there is a limitation to the amount of cooling that practically can be provided by the ventilation system. To increase the cooling capacity and to decouple the control of air quality and thermal comfort, the ventilation system can be accompanied by a hydronic system for heating and cooling.

What are the options?

Normally, when air is used to handle indoor air quality and comfort cooling, heating is provided by a water based system such as under fan coil units, floor heating or radiators. Another option is a waterborne climate solution which can handle both cooling and heating by the means of a water circuit, examples are fan coil units, radiant ceilings and active chilled beams. With the latest advancements of active chilled beams, a hybrid solution of air and water has entered the market. By adding clever control systems to such a solution, it is possible to capture the essential benefits of both air and water, free cooling and large cooling/heating capacities.

CAV solutions

Normally an active chilled beam solution is designed to operate with constant air volumes (CAV). The primary air flow is then designed to handle the latent heat loads and remove impurities to ensure good indoor air quality. Traditional active chilled beams are designed with nozzles of fixed size, giving a fixed k-factor. To deliver different primary air flows, the size and/or number of nozzles have to be varied. Meaning, if the use of a space is repurposed during a design phase or in a refurbishment project, products need to be replaced to make sure the right amount of fresh air is delivered for the new use of the room. However, with the latest developments of active chilled beams, the nozzles are replaced by openings in the pressure chamber whose size can be adapted. The k-factor is then not fixed, but variable. The amount of supply air delivered can then be altered by changing the k-factor, in general easier than replacing the product.

VAV solutions with active chilled beams

In cases where it is desirable to use a traditional active chilled beam under variable air volume (VAV) conditions, an air flow damper is installed in front of the unit, to modify the duct pressure upstream of the active chilled beam. However, the relationship between duct pressure and air flow is not linear, it rather follows a quadratic relationship which means that when the air flow is reduced by 50%, the duct pressure has to be reduced to 25% of the design pressure. At low primary air flow rates the duct pressure becomes very low and the speed at which the air enters the room also low. Then there is a risk that the Coanda effect will not be maintained which results in an increased risk of problems with draught. Meaning, the realistic range in which the supply air flow can be turned down is somewhat limited. There are also limitations to the increase in air flow. Boosting the air flow means that the duct pressure has to be increased. Doubling the primary air flow rate gives a quadrupling of the duct pressure. This is unreasonable in most applications because the generated noise levels will increase rapidly with air speed. In sum, traditional active chilled beams with fixed nozzles can be operated in VAV conditions, but within a limited range of primary air flow.

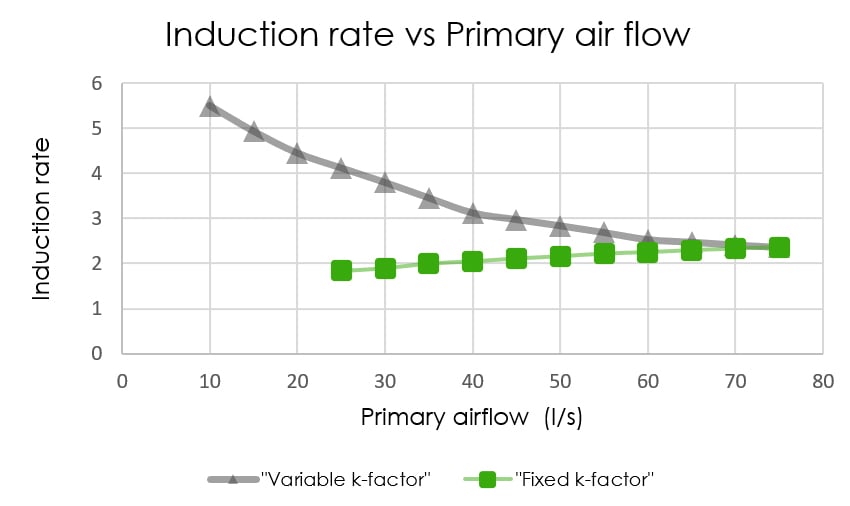

Another drawback of modulating the duct pressure, is that the induction ratio is more or less constant with a fixed k-factor. Meaning, as the primary air flow is reduced, the amount of induced room air is reduced proportionally, and hence is the heating/cooling capacity available from the water side significantly reduced at reduced primary air flows.

Variable k-factor for VAV solutions

Modern active chilled beams with variable nozzle sizes can operate at different primary air flow rates while maintaining the duct pressure constant. As the primary air flow rate is reduced, the size of the openings in the pressure chamber is reduced too, as well as the k-factor. This results in an increased induction ratio. In practice this means that the amount of induced air is not reduced linearly with the primary air flow. This enables high induction rates and good cooling/heating capacities also at low air flow rates. The maintained duct pressure ensures that the speed of the supply air is kept at a level that can maintain the Coanda effect. Further, it is possible to increase the primary air flows without increasing the duct pressure, meaning, a single product can deliver a wide range of primary air flows.

Induction rate as a function of primary airflow. With variable k-factors the size of the opening in the pressurised channel decreases as the air flow is modulated down resulting in an increased induction rate. In case a fixed nozzle beam is used and the primary air flow is modulated with an upstream damper the induction rate is more or less constant.

Control strategies as the product has a wide working range

Moreover, active chilled beams with variable k-factors can be operated as described above, over a wide range of primary air flow rates, which allows for different control strategies to be considered.

In case there is a need to change the temperature in the room, a number of parameters may be changed in order to adjust the amount of cooling/heating delivered to the room. The primary airflow and temperature as well as the amount and temperature of water flowing through the coil of an active chilled beam can be adjusted which controls the amount of heating/cooling delivered to a room. What is the best alternative, will depend on the situation and on the system design. If it is cold and dry outside, it might be advantageous to increase the air flow when there is a need to increase the amount of cooling. At another point in time the conditions might be different and it will be more efficient to increase the flow water rather than to increase the air flow.

Since active chilled beams rely on the induction of room air in order to generate a flow through the coil, the primary air is always mixed with room air that can be cooled, heated or, in case the water valves are closed, unaffected by the coil. With this reasoning, an active chilled beam can be seen as an induction diffuser making it possible to operate with lower primary air temperature than most diffusers, without facing issues with draughts. The advantage of this would be a possibility to deliver more cooling via the ventilation air or reducing the primary air flow rates needed to deliver a moderate amount of cooling, which will make the use of free cooling even more efficient. Active chilled beams with variable k-factor or VAV beams can be considered a hybrid solution that, if combined with a clever control, captures the benefits of both airborne and waterborne climate solutions.

At Swegon we offer all types of waterborne and airborne climate solutions, with different alternatives of controls and functionality, both on a room and system level. Do not hesitate to contact us, we are happy to help you with a suitable solution for your next project.

.jpg?width=75&name=Image%20(5).jpg)

.jpg?width=75&name=magnus%20andersson_550x550%20(1).jpg)

.jpg?width=75&name=0%20(1).jpg)

-4.png?width=75&name=MicrosoftTeams-image%20(3)-4.png)