Imagine if you were forced to choose between a room that can’t be cooled in hot weather, or a room with a constant cold draught. You’d be hard-pressed to choose, right? Happily, you don’t have to. Thanks to the physical principle known as induction, there is the option of ventilating and heating or cooling spaces so as to achieve the perfect indoor climate all year round.

In a ventilation context, induction refers to the effect caused when a high-speed jet of air passes stagnant air. That jet of air drags with it the ambient air, mixes with it and increases in volume.But why is induction so important?

One reason is that we can use that induction effect to introduce high cooling or heating capacity into building spaces without any risk of causing local cold draught spots in the room, causing discomfort to the building occupants.

If you want to supply air and cooling into a room by means of an air diffuser, then the induction causes the supply air jetting from the air diffuser to maintain a relatively low temperature of 18 °C, say. Because the air jets entrain the warm ambient air and mix with it, the air can achieve a comfortable temperature before it reaches the occupied zone.

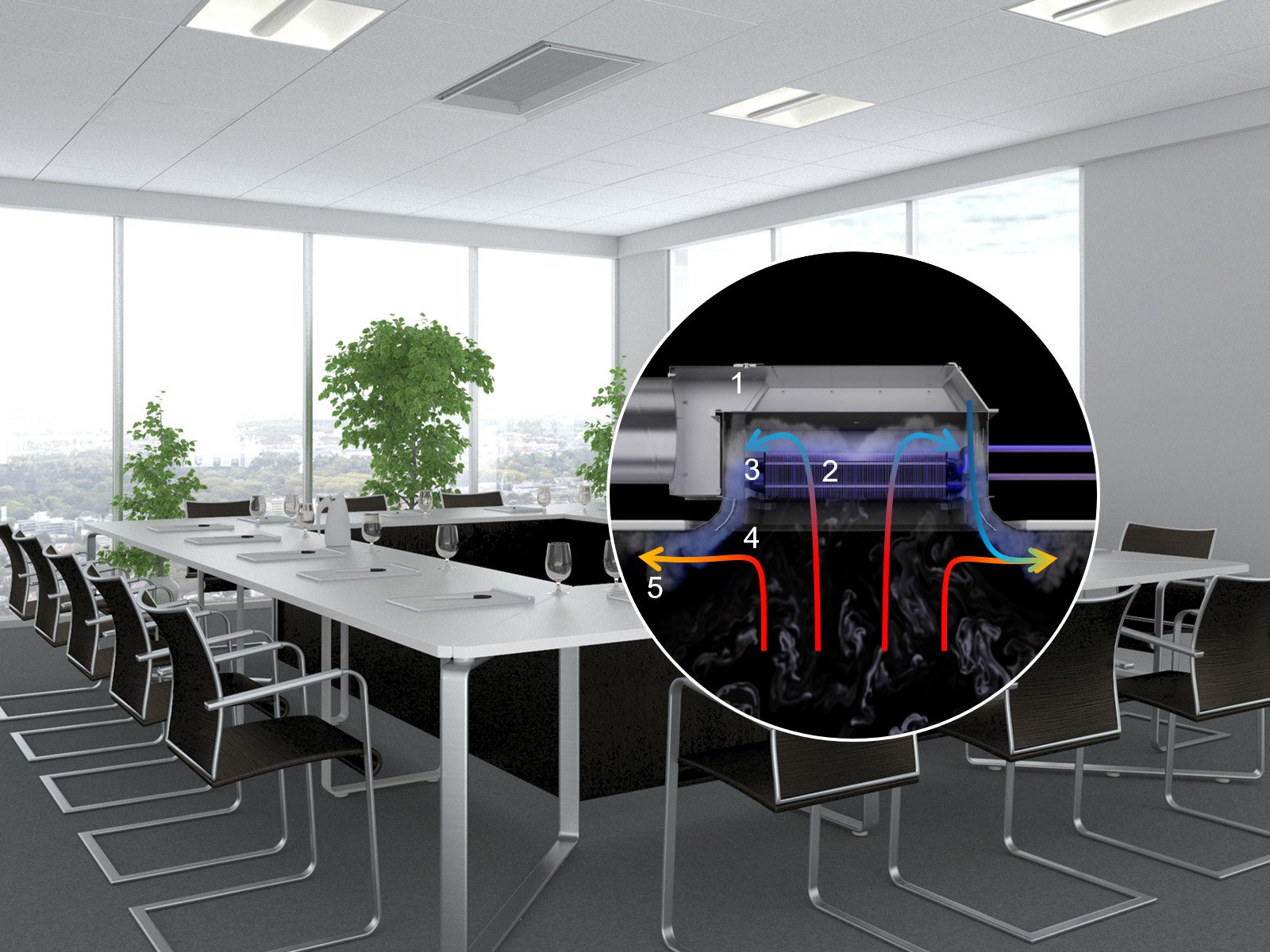

This is what we refer to as basic induction, but there are also products that harness the induction for a dual effect, such as chilled beams and comfort modules based on waterborne cooling and heating. If we look at a cross-section of a comfort module, we can trace how the air moves through the product via a number of stages:

How the air moves through the comfort module in five steps

1. Cold supply air from the air handling unit builds up overpressure, which is ejected in small jets inside the unit.

2.Induction drags with it the ambient air, which causes underpressure and sucks in warm air from the room, which is cooled as it passes through a water coil.

3. The supply air is now mixed a first time with the air from the room, which increases the air volume and lowers the temperature.

4. Next, the air flows out along the ceiling and induction causes the supply air to mix for a second time with the ambient air.

5. When the air flows out into the room high cooling capacity has been introduced, but since the cool air has been “diluted” from being mixed with the room air, the air flow is at a comfortable level, without the risk of uncomfortable cold draught.

In this way, an original supply air flow rate of 20 l/s at a temperature of 18.0 °C (stage 1 in the illustration above), and a flow through the water coil at 14 °C, is transformed into an air flow of 190 l/s with a pleasant temperature of 20.4 °C (stage 5 in the illustration above).

Induction thus serves as a “mixer” which causes the cool supply air and the warm ambient air to combine into a comfortable temperature. In addition, the induction serves as an “engine” to drive the air through the water coil to provide an extra cooling effect.

The result is fresh air at the right temperature without noisy fans or the risk of uncomfortable cold draught in the occupied zone. Ingenious!

.jpg?width=75&name=sigvardsson_220628_0008_small_webb%20(1).jpg)